Introduction

Since prehistoric times, it is known to ferment sugary and

other materials to alcohols, extract harmful compounds from the

fermented product and preserve useful ones. However, even in the

industrial manufacture of noble beverages (cognac, brandy) by

distillation, neutralization, purification and other methods, harmful

substances are not completely removed.

During the primary distillation of fermented products, along

with alcohol, a mass of harmful substances, including poisons:

methanol, fuel oils, and other untreated compounds, is also

distilled. The boiling point of alcohol is 78.4 °C, and in fermented

products there are liquids that boil at lower (methanol, acetone,

acetaldehyde, etc.) and at higher temperatures (amyl, propyl,

isoamyl and other alcohols, furfural, acetyl). Many of them

are poisonous and dangerous to humans. However, during the

processing of fermented products with the separation of fractions,

with the removal of the most toxic impurities in the final product,

there are still quite a lot of harmful components called fuel oils. In

a high-quality alcoholic liquid should contain as little fuel oils but

should be kept harmless substances. The approximate content of

fuel oils in some products (Table 1).

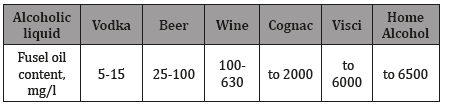

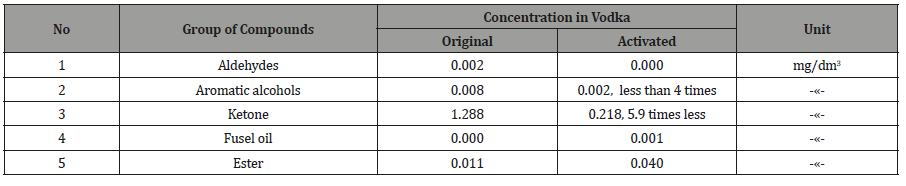

Table 1: Approximate content of fuel oils in alcoholic liquids.

Fuel oils contain high-molecular alcohols, which are difficult to

break down due to the complex composition of the human body.

Therefore, the work human liver is complicated, the decontamination

of toxins is slowed down, as from the management of the extended.

To break down substances, they must be oxidized by blood oxygen.

But the longer their molecules are, the more oxygen they need.

When using large doses of alcohol blood supply is difficult, oxygen

is not enough, so the toxins are not completely oxidized. In this

case, things are formed more poisonous than methyl alcohol. With

a large content of acetaldehyde, the possibilities of the liver to

neutralize ethanol are sharply reduced, its proces-sing is delayed, and

the concentration of acetaldehyde increases several times due

to its further formed during the decay of ethanol.

In General, the product obtained after distillation of the initial

fermented and fermenting substances contains impurities divided

into groups:

1. Hats with a boiling point of 78.4 °C below: acetic-butyric

ether, acetaldehyde, acetone.

2. Intermediate, as main components.

3. Tail (fuel oil) with a higher boiling point and lower

volatility than ethyl alcohol: monoatomic alcohols: propyl,

isopropropyl alcohol and its isomer, propanol-1, amyl, isoamyl,

isobutyl and methyl alcohols, furfural, acetyl, ethyl acetate,

ethyl butyrate and other toxic compounds; the most dangerous

of them isoamyl alcohol (isoamyl alcohol C5H4OH), giving up to

60% of the volume of fuel oils.

In fuel oil are also found: n-propyl, n-butyl, hexyl alcohols,

diethyl ether, methyl acetate, methylpropionate, diacetyl, as well as

acids: acetic, propionic, isobutyric, n-oil, isovalerian, n-valerian and

more than 40 substances. And Isabella grapes during fermen-tation

also produces hydrocyanic acid.

The largest amount of fuel oils produced from grain raw

materials, when the alcohol raw them of 0.2-0.4%. The content

of fuel oils in vodka is limited by standards: for vodka «special

purification»-no more than 15.0mg/l, for vodka «extra» up to

10.0mg/l, for vodka «Lux»- 5.0mg/l. In 0.5 liters of «normal» vodka

on average contains 4ml of fuel oil. Especially dangerous isopropyl

alcohol, which as its «cuts» a person, turns off consciousness, and

possible death. For the average person, 1.5 liters of ordinary vodka

is enough to get a lethal (13-15ml) dose of fuel oil.

Methods of cleaning from fuel oils: It is mainly used

rectification of liquids, i.e. their separation into components

(fractions) substances with a close boiling point. To do this, the

liquid is heated to the boiling point and evaporation of the first

fraction, it is kept heated and the first fraction is extracted by vapor

condensation. Further, the temperature for evaporation of the

second fraction is increased and it is similarly extracted as a useful

raw material. After that, the distillation can be stopped.

The industrial method of cleaning from fuel oils is carried out

in distillation columns in vertical cylindrical vessels of constant or

variable cross section, equipped with heat and mass transfer devices

and auxiliary units for the separation of liquids into fractions. The

heated liquid is fed into the column from below, the light fractions

are concentrated in the upper part of the column, and the heavy

ones with a higher condensation temperature are concentrated in

the lower part. Lack of rectification is the duration, complex, very

сu-mbersome installation, high costs of thermal energy.

In private, alcohol purification is used by entering 3-5g/l of

potassium permanganate (KMnO4) into them, settling for up to

10 days, precipitating a dark precipitate and draining the liquid

without sediment. Enter also on 50g/l of wood activated carbon of

industrial brands, defend liquid of 20-30 days, filter through paper

or cotton filters with the activated carbon. Apply and freezing

harmful substances, their deposition and draining the liquid

without impurities. These long-term processes require freezers

and other devices, special substances.

Innovation in alcohol purification:Tambov state technical

University to clean alcohol from fuel oils tested combined static

mixer-activator according to Russian patent No. 2411074 [1]. The

peculiarity of the activator is that: it carries out mechano-chemical

dispersion of long-chain organic liquids, passed through it [2,3].

The use of the activator simplifies the process, reduces the content

of sea-wool oils by at least 10-13%, some toxic substances in simple

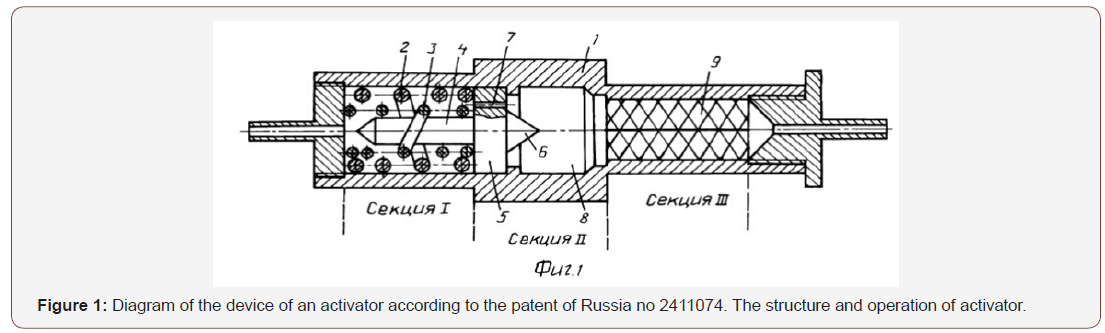

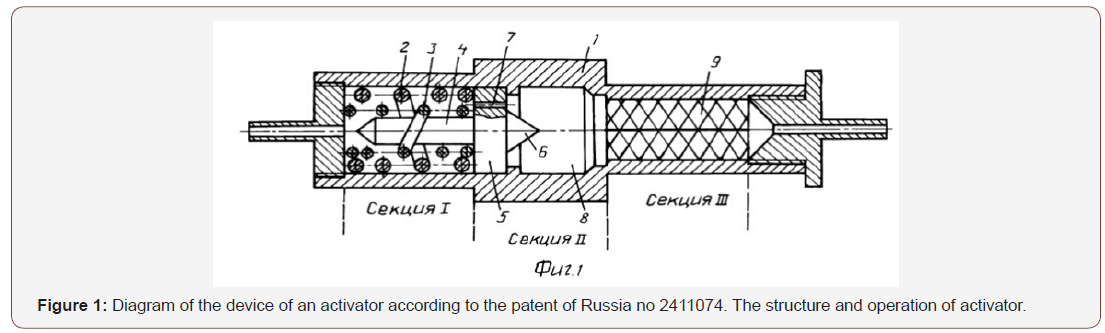

waters up to 3 times, esters by at least 8 times (Figure 1).

In the cylindrical housing 1 of the activator there are sections

chambers I, II, III. In the section of the chamber I mounted the screws

2 and 3. The screw 2 is adjacent to the inner surface of the housing

1 and has a right side or left side winding. Inside the screw 2 with

a small gap mounted screw 3 with the opposite winding. Inside the

screw 3, also with a small gap, a rod 4 is mounted, combined with a

disk 5 having a cone 6 on the reverse side.

In disk 5 microchannels 7 are made, the centers of which are

located in the gap bet-ween the screws 2 and 3. For a disk 5 is

mounted the second (II) cavitation section 8, followed by section-

III camera, which features a lattice design 9 with a narrow slit

width of 0.1-0.5μm, At the beginning, the liquid is controlled on a

chromatograph for the initial content of harmful substances, then

heated to 25-28 °C. Setting the flow rate of the 10cm/s, pump it through

the activator. In it, in the first chamber, clusters of fuel oils

are rubbed with vortex counter flows between the external and

internal screws. Then the liquid is injected through microchannels

into the second vacuum chamber rarefaction, where the molecules

of the oils are dispersed cavitation. Finally, the liquid is pumped

through the broken slots of the structure 9 of the third chamber,

which finally disperse and activate the molecules of fuel oils and

provide further activation of alcohol for a long period.

Therefore, liquids are kept for up to 30 days, the third time

they control the content of fuel oils and when they are reduced by

at least 10%, they are given a liquid for processing or a finished

product. Activation of alcoholic liquids not only reduces the content

of fuel oils, but also increases the content of useful components in

them.

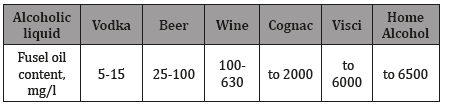

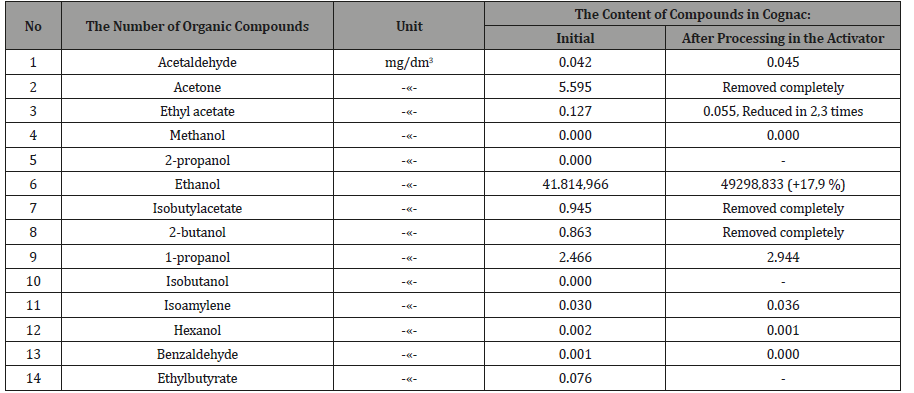

Examples of testing method: 21.02.2018 «Cognac» checked

on the content of organic components on the gas chromatograph

«Cristallux-4000M» (with column HP-FFAP 50 mx0/32x50um

and detector PID-1) in Tambov certified laboratory of forensic

and medical examination. Then the drink was pumped through

the activator and similarly checked the content of the components

(Tables 2,3).

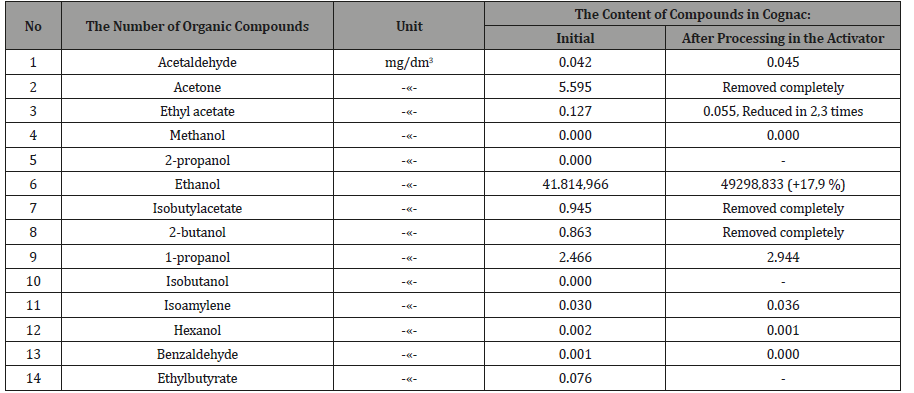

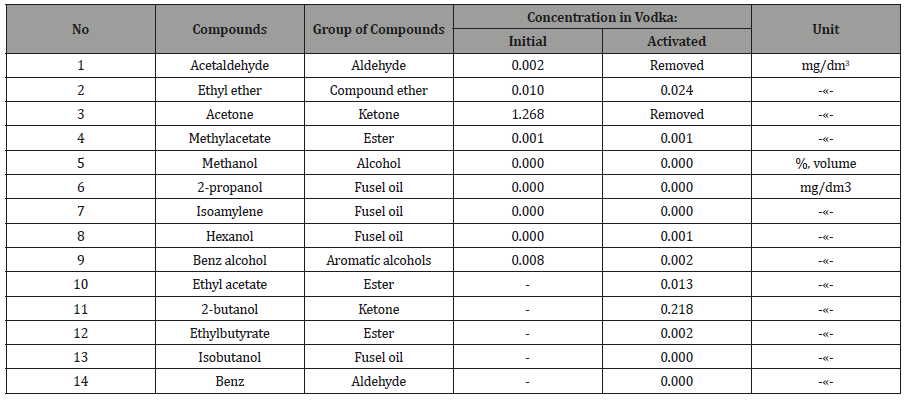

Table 2: Complete results of the control components in cognac.

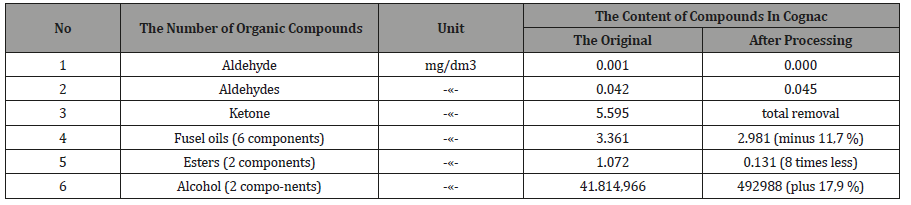

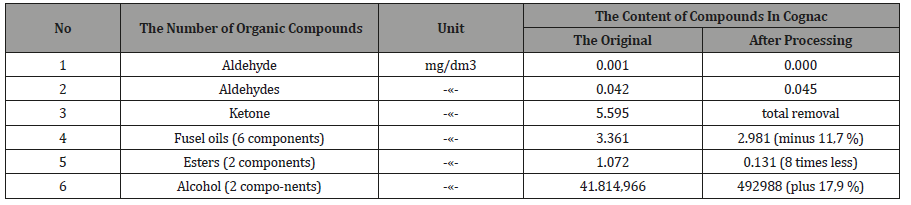

Table 3:

Table 3: Summary results of control of components in cognac, The summarized results of the control components in brandy.

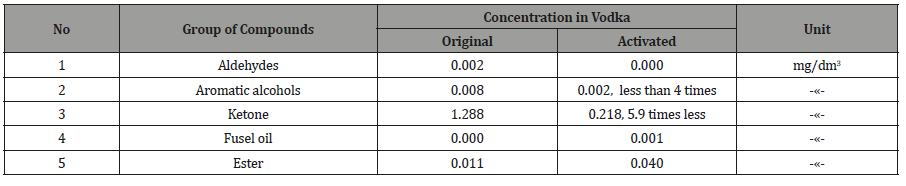

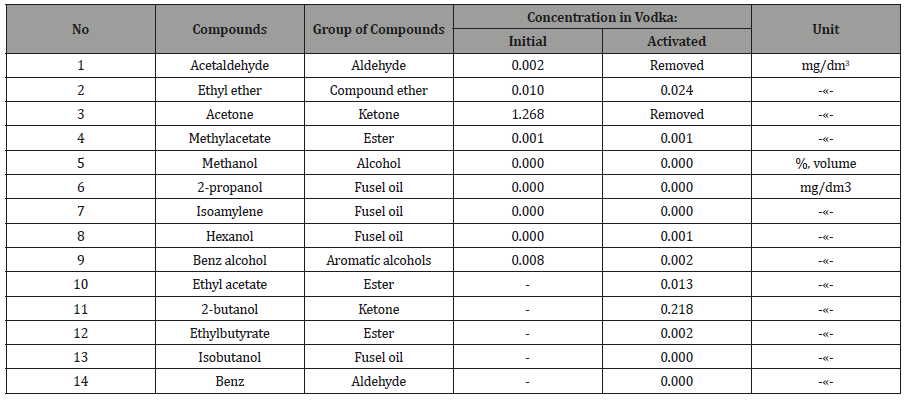

18.04.2018 vodka production was similarly tested on the

content of toxic components, after which it was pumped through

the actuator and checked again (Table 4, 5). From Tables 2-5 it

follows, that activated the «Cognac» acetone, ketone, the isobutyl

acetate and 2-butanol is completely removed, ethyl acetate is

reduced in 2,3 times, the six components of oil decreased by 11.7%,

the two components of esters 8 times, and the two components of

the alcohols increased by 17.9%. Similarly, in vodka acetaldehyde

and acetone are removed, aromatic alcohols were less than 4 times

that of the ketone at 5,9 times.

Table 4: Approximate content of fuel oils in alcoholic liquids.

Table 5:

Table 5: Changes in vodka content of organic compounds.

Other testing results

1. In the wine «Cabernet» after activation the content of

fuel oils decreased from 2,3mg/dm3 to 0,971mg/dm3, i.e. 2,37

times.

2. In white dry wine-3 times.

3. And in sweet fortified wine-100 times.

Acknowledgment

None.

Conflict of Interest

No conflict of interest.